-

EMC - Products

-

Vacuum Coating

CLOSE

Overview

Several examinations show that certain metallic or oxidic coatings reduce or inhibit the growth of Viruses/Bacteria/Fungi on surfaces and are even able to kill organisms directly.

The results can be:

Layers with confirmed antimicrobial properties are:

Pure silver layers have increasing application in the medical sector [1]. In the past few years the focus of research increasingly fell on the antimicrobial properties of copper surfaces. A British study in 2015 [2] confirmed highly antimicrobial characteristics of copper, which in solid form can prevent contact transmission and spreading of respiratory viruses. Research results of the University of Southampton show that corona viruses, when in contact with copper or copper alloy surfaces can be deactivated within minutes. Similar results have been obtained in the USA at Princeton University and the University of California in Los Angeles. Deactivation speed of the virus increases with the copper content. On massive copper its destruction is complete and irreversible. However, on common materials like stainless steel, glass, plastic, or ceramic tilling, its existence exceeded five days. [2]

Mode of Action:

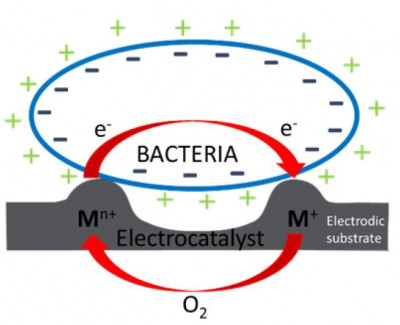

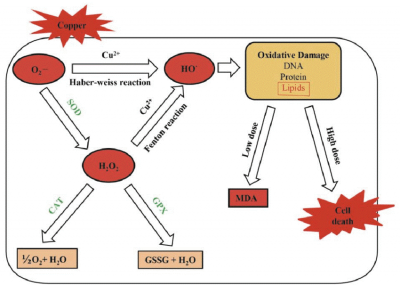

Droplets with pathogens/host cells get in contact with the copper surface => Cu2+ ions solve an diffuse through cell membranes [3], causing an electric current in opposite direction of the active cell membrane transport [4]. Peroxidation reactions open the cell membranes [5] and cause the cell to loose plasma which results in metabolic failure [6]. Cu2+ oxidize and destroy cell organs and their DNA/RNA [4] [7]. A good effect against cells is preferably achieved by a sufficiently rough surface [8]. Maximization of surface area can be increased by a porous PVD layer structure. Copper oxide patina can change the antimicrobial behavior [9].

Figure 1: Copper ion current through cell wall. [6]

Figure 1:lipid membrane peroxidation mechanism and cell poisoning [10]

Antimicrobial layers at ROWO

Using PVD techniques (sputtering and vapor deposition) ROWO Coating can deposit the antimicrobial layers copper, copper alloys, silver, silver alloys and titanium dioxide on film, wovens and nonwovens from roll 2 roll. Layer thicknesses range from a few nm to several µm depending on customer specifications.

At present we are coating different antimicrobial layers for several customers. Applications are band-aids, respiratory masks and filters.

[1] [Online]. Available: https://www.wotech-technical-media.de/womag/ausgabe/2015/09/28_ganz_pvd_09j2015/28_ganz_pvd_09j2015.php.

[2] "Appl Environ Mircrobiol 81:," Appl, pp. 1085-1091.

[3] J. O. C. Donskey, "Transmission of SARS and MERS coronaviruses in healthcare settings: the possible role of dry surface contamination," 28 6 2015.

[4] [Online]. Available: https://de.wikipedia.org/wiki/Membrantransport.

[5] [Online]. Available: https://www.bonn-copper.de/KupferGesundheit.

[6] [Online]. Available: https://en.wikipedia.org/wiki/Lipid_peroxidation.

[7] [Online]. Available: https://www.bonn-copper.de/KupferGesundheit.

[8] [Online]. Available: https://www.sciencedirect.com/science/article/pii/S0010938X17313963.

[9] O. H.-R. e. al., "Antimicrobial Coatings for Touch Surfaces," p. 5.

[10] [Online]. Available: http://www.laborundmore.com/archive/335904/Warum-sterben-%C2%ADBakterien-auf-%C2%ADKupferoberflaechen%3F.html.

[11] [Online]. Available: https://www.researchgate.net/profile/Vinitha_Ebenezer/publication/325512135/figure/fig3/AS:634135286661121@1528201042068/A-schematic-view-of-variation-in-lipid-peroxidation-and-SOD-activity-in-the-green-algae.png.