-

Vacuum Coating

-

EMC - Products

CLOSE

In thermal evaporation, the wire-shaped coating material is continuously fed onto resistance-heated crucibles. The wire first liquefies and then passes into the gas phase in the form of a vapor cloud. The substrate to be coated is passed over a rotating, cooled roller, which is positioned just above the crucibles. This causes the coating material to vaporize onto the substrate, where it then condenses and forms the desired layer.

The evaporation speed and, in conjunction with the web speed of the substrate, the desired coating thickness can be set via the wire speed and the temperature of the crucibles.

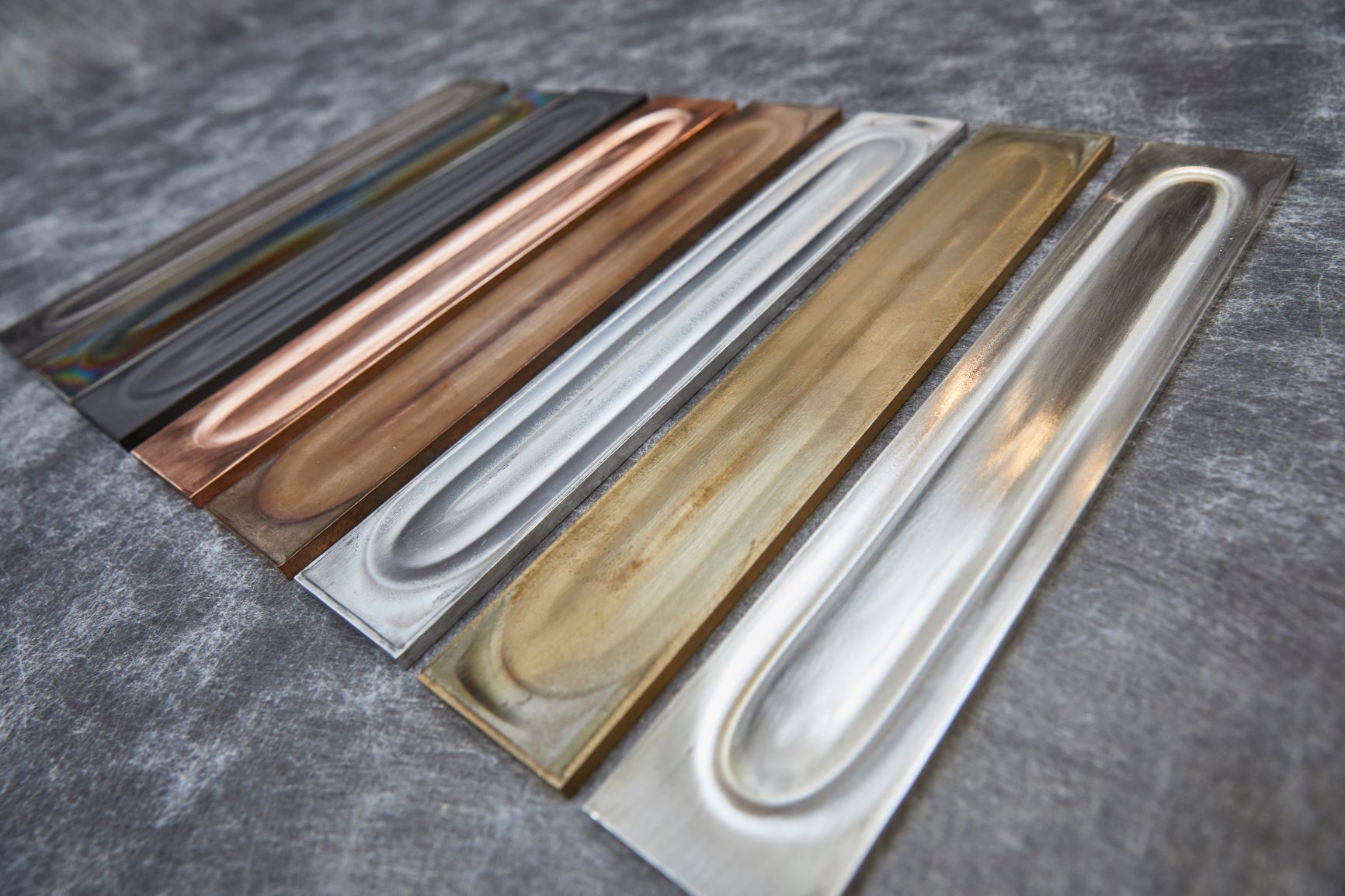

For cathode sputtering, we use magnetron sputtering, which has proven to be the most economical process in practice. In this process, the coating material is used in the form of plates or tubes (targets). An electric field is generated between the target and the substrate, with the target at negative potential.

A plasma is generated within the electric field, consisting of positive argon ions, electrons and neutral particles. Due to its extraordinary properties, plasma is often referred to as the fourth state of matter.

The resulting metal vapor condenses as a thin layer on the passing substrate.

Compared to thermal evaporation, sputtering offers advantages in terms of a larger selection of coating materials, better adhesion of the coating material to the substrate and a more uniform coating thickness distribution.

In order to achieve optimum adhesion even on low-energy surfaces, ROWO can subject the substrates to plasma modification.

Using a plasma system upstream of the coating station, we are able to clean and activate the substrate surface inline directly before metallization. The low-pressure plasma is generated by a bipolar pulsed glow discharge. By varying the coupled power, the gases used and the path speed, the surface modification can be specifically optimized for the different substrate materials.

Compared to a corona discharge, which is operated at atmospheric pressure, the low-pressure plasma has plasma particles with significantly higher energies, which achieve a much more effective activation and cleaning of the substrate surface. While the corona pre-treatment wears off very quickly, the pre-treatment in the low-pressure plasma is stable over a much longer period of time. In addition, the low-pressure plasma is very homogeneous compared to the corona discharge, which leads to a more uniform treatment of the surfaces.

Suitable gas mixtures can be used to generate specific functional groups and radicals on the polymer surface, which significantly improve the surface energy and thus the wetting/adhesion of subsequent metallization, printing or painting.

ROWO also offers this plasma pre-treatment as a contract pre-treatment for customers' own substrates.

With your ROWO contact person you are in the best hands when it comes to your questions. You always have the security of getting exactly the solution that suits your company or purpose. Your ROWO contact person is committed to you and your personal contact person for all questions. Or you can use our contact form. We look forward to your message!